- Reliable overpressure protection: Automatically releases excess pressure to safeguard equipment.

- Industry-standard compliance: Designed according to DIN 3320, DIN 3202, DIN 2543-2545, and tested per DIN 3230.

- Durable construction: Made from GS-C25, stainless steel, Stellite, and copper alloy for longevity.

- Versatile applications: Ideal for hot oil, steam, and water systems in industrial environments.

- Efficient installation: Can be placed in pipeline commutation to reduce welding requirements.

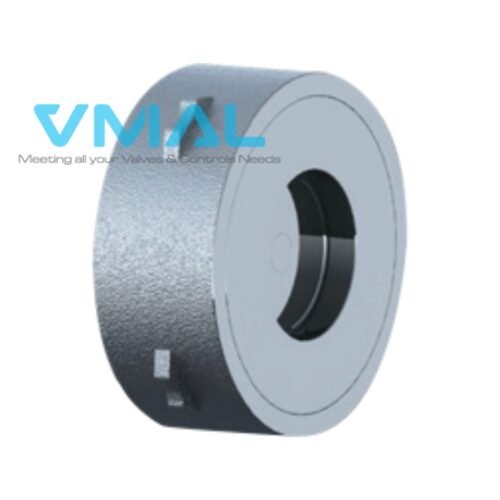

VMAL Boiler Safety Valve

Description

In the demanding environment of industrial and commercial boiler operations, ensuring the safety and integrity of your systems is paramount. Valvelink, a trusted partner in providing comprehensive valve and control solutions, is proud to introduce the VMAL Boiler Safety Valve. This meticulously engineered valve is designed to offer superior protection for a wide range of applications, including hot oil systems, steam systems, and hot and cold water systems.

The VMAL Boiler Safety Valve stands as a critical component for safeguarding pressure-sensitive equipment from overpressure events. Designed and manufactured in compliance with rigorous DIN standards, this valve provides a reliable and automatic release of excess pressure, preventing catastrophic failures and ensuring operational continuity.

Adherence to International Standards

The VMAL Boiler Safety Valve is built to meet stringent international standards, guaranteeing its quality and performance. The key design and testing specifications include:

- Design Standard: DIN 3320

- Face to Face Dimension: DIN 3202

- Flanged Ends: DIN 2543-2545

- Test & Inspection: DIN 3230

This adherence to established DIN standards ensures that the VMAL Boiler Safety Valve will integrate seamlessly into existing systems and perform reliably under pressure.

Superior Construction and Materials

Valvelink has selected premium materials for the construction of the VMAL Boiler Safety Valve to ensure its durability and performance across various demanding applications. The meticulous selection of materials for each component guarantees longevity and resistance to corrosion and high temperatures.

Main Component Materials:

| Part Name | Material Options |

| Body | GS-C25, 1.4301, 1.4401 |

| Cover | GS-C25, 1.4301, 1.4401 |

| Seat | 1.4301, Stellite |

| Disc | 1.4021, 1.4301+Stellite |

| Spring | 1.4301, 1.4401 |

| Double-headed bolt | ASTM 193-B7, A193-B8 |

| Nut | ASTM 194-2H, A194-8 |

| Gasket | Stainless steel Flexible graphite |

| Copper guide sleeve | Copper alloy, D2, BL2 |

The use of high-grade materials like GS-C25 for the body and cover provides excellent strength, while options like stainless steel (1.4301, 1.4401) and Stellite for the seat and disc ensure exceptional durability and resistance to wear and corrosion.

Key Advantages for Your Business

The VMAL Boiler Safety Valve is not just a component; it is an investment in the safety and efficiency of your operations. One of its key installation advantages is its ability to be installed in the commutation of the pipeline, which helps to reduce the amount of welding required. This simplifies installation and maintenance, saving both time and resources.

By choosing the VMAL Boiler Safety valve, you are prioritizing the protection of your assets and personnel. Valvelink is committed to providing not just a product, but a complete solution that meets all your valve and control needs. Trust the VMAL Boiler Safety Valve for uncompromising performance and peace of mind.