SOLUTION & SERVICES

- GREEN & HIGH VALUE-ADD PRODUCT DEVELOPMENT & MANAGEMENT AND COMMERCIALIZATION

- Invention Commercialization Viability Studies

- Development and Market-ready Prototyping of New Product and Technologies

- Analysis and Design for Best Processing and Manufacturing Practices

- Intellectual Property Rights Management

- Market Research and Assessments

- Development of Business Plans

- Funding, Investment, Business Matching and Consultancy

- HEAT AND POWER GENERATION TECHNOLOGIES

- Fossil Fuel and Biomass Steam Boilers

- Heat Recovery Steam Generators

- Thermal Oil Heaters

- Industrial Power Cogeneration

- INDUSTRIAL PROCESS PLANTS

- Industrial Steam Plant and Automation

- Rubber Glove Manufacturing Plant

- Timber Processing & Drying Plants

- Fish & Feed Meal Plants

- Mineral Oil Blending Plants

- Crumb-rubber Drying Plant

- GREEN CONSULTANCY & ENERGY MANAGEMENT SERVICES

- Plant Surveys, Energy Audit and Energy Management Services

- Energy Conservation Studies and Implementation

- Manufacturing Process Productivity and Efficiency Upgrading

- Industry Process Development and Design

- Industrial Process Automation Development and Design

Design, Fabricate, Install and Commission a 10 Ton Capacity Ekoprena Processing Plant.

Ekoprena is a form of epoxidized natural rubber (ENR) and is an established class of specialty rubber obtained by epoxidation of natural rubber (NR) latex.

Ekoprena is a green material as it is produced from a renewable natural source unlike synthetic rubber which are derived from non-replenishable petroleum.

Valvelink Asia Contracted Exclusively to Design, Fabricate, Install and Commission a Commercial Scale Processing Plant basing on Malaysian Rubber Board’s (MRB) Pilot Scale Research Unit for the Manufacturing of the all New Green Rubber Technology.

Ekoprena is an National Key Economic Area Project (NKEA) Spearheaded by the Countries Performance Management and Delivery Unit (PEMANDU), Technology by Malaysia Rubber Board (MRB), Developed by FELDA and Hardware Design by Ecotherm Sdn Bhd

Customer : FRI Palong 8, Negri Sembilan

Location : Malaysia

Project Value : USD 1.5 Million Year : 2011/2012

1.Design and Supply of 1 nos of 15 tons High Pressure Biomass Steam Generators c/w the full operation plant of piping, heat exchangers and controls.

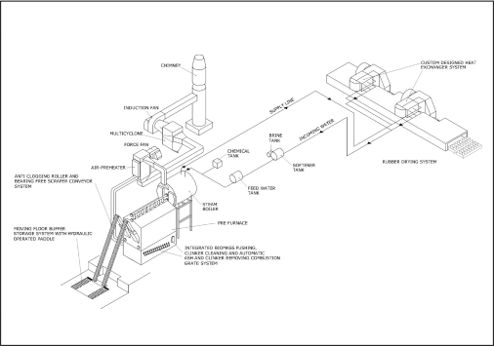

2.Design and Supply of Patented Crumb-rubber Indirect Drying System for 2 nos Process Plants as Alternative to existing Diesel-Fired Direct Hot Air Generation for the purpose of Energy Cost Savings.

Customer : FRI Palong 8, Negri Sembilan

Location : Malaysia

Project Value : USD 1.72 Million Year : 2007/8

Scope of Works:

To Design, Fabricate, Erect, Test and Commission, and Guarantee;

1. One System of Steam Heat Energy Generation Plants comprising of:

- Biomass Dynamic Pusher Grate Combi Type High Pressure Biomass Steam Boiler System for Palm Fibre and kernel Shell Firing

- Biomass Moving Flow Bunker c/w Automatic Conveyor Feeding System

- Environmental Control Multicylone Dust Scrubber System

- Flue Gas and Combustion Control Induce-fan Exhaust System

- Combustion Air Preheating System for burning wet Fuel

- Steam Piping, Pressure Regulation, Condensate and Flash Steam Recovery Systems for two process plants

2. Two Nos Crumb-rubber Indirect Hot-air Drying System for 2 nos Process Plants comprising of:

- 15 stations of Hot-air Generators with alternative heat inputs from either direct diesel burners or from steam heat exchangers c/w by-pass and quick-change dampers

- 45 unit of custom designed fintube heater batteries of 1.0 million BTUs each with designs for fast interchange for chemical washing.

1.Design and Supply of 2 nos of 24M Kilojoules/hr Thermal Oil Biomass Heat Energy Generators c/w the full operation plant of piping, pumping, heat exchangers and controls.

2.Design and Supply of 6 nos of Patented Double-Tiers Glove Dipping Conveyor System for 6 nos of Glove manufacturing machines.

Customer : APL Vietnam, Go Dao Industrial Estate, Long Thanh

Location : Vietnam

Project Value : USD 2.46 Million Year : 2007

Scope of Works:

To Design, Fabricate, Erect, Test and Commission, and Guarantee;

A) Two Systems of Biomass Thermal Oil Heat Energy Generation Plants comprising of:

- Biomass Dynamic Pusher Grate Oil-Walled Furnace with Double Helical Convection Coils Thermal Oil Heat Generator, for Woodchips and Coal Firing.

- Biomass Conveyor Feeding System

- Environmental Control Multicylone Dust Scrubber System

- Flue Gas and Combustion Control Induce-fan Exhaust System

- Thermal Oil Expansion and Deaeration System

- Piping and Pumping System for the whole plant

- Temperature Regulation and Control System for the process

B) Six Nos of Patented Double-Tiers Glove Dipping Conveyor Systems comprising of:

- Double-Tiers Dipping Conveyor System of 1000m length x 6 lengths

- Conveyor Guides and Tracks for Process Functions

- Fintube Hot Air Heat Exchangers for Gloves and Formers Drying, Gelling and Curing

- Stainless Steel Submerged Coil Heat Exchangers for Liquid Heating for Slurry, Leaching and Washing

- Control Valves and Systems for Process Temperatures Regulation

Designed and supplying of Patented Eco-friendly Light Weight Expendable Metal Pallet (E-pellet) for the purposed of packaging and transportation of solid or liquid products. The unique design of the disposable metal pallet is 12 kg in weight yet able to support up to 4.0 tons of loads. The product is successfully commercialized and marketed to companies like Goodyear and Bridgestone for their transportation of rubber in the region for tires processing.

Customer : Goodyear and Bridgestone

Location : Malaysia (HQ) and Indonesia

Project Value : Total USD 1 Million Year : 2003

Scope of Works:

Manufacturing and supply of disposable E-pellets to customers for the transportation of crumb-rubber bales in replacement of wooden crates and metal boxes.

The E-pellets increase operational efficiency of the customers as compared to the conventional methods. The metal pellet replaces current timber packaging which is non-environmentally friendly.

Key features of E-Pallet:

- Lightweight. 12kg in weight. Lightest disposable metal pellet in the world compared to any metal pallet in the world.

- Rigid & High Strength. Dynamic Handling Load of 2.8 tons and Static Load of 4.0 tons.

- Competitive Pricing. Due to the low production cost and innovative design and use of materials , the pricing of the E-Pallet is the lowest in the market

Recyclable. E-Pallets are disposed and sold as scrap metal for recycling after use.

Design and Supply of package Steam and Thermal-oil Heat Energy Generators complete with the full distribution and heat-transfer plants of piping, pressure reduction, condensate recovery, heat exchangers and process controls for Felda Rubber Industries (the largest Government owned group of companies for palm oil and rubber plantations and products). Supply period from 1988 to 2006 (18years)

Customer : Felda Rubber Industries, Dioh and Plg15

Location : Malaysia

Project Value : Total USD 12.75 Million Year : 1988 to 2006

Scope of Works:

To Design, Fabricate, Erect, Test and Commission, and Guarantee;

- 1988- Conversion and supply of steam heated rubber glove manufacturing system complete with 2 x 5tons/hr boiler, steam distribution system, hot-air/hot-water heat-exchangers, and control system for 4 nos of glove manufacturing lines.

- 1991- Supply of steam distribution and heating system to hot-presses for rubber products molding complete with 1 x 4 tons/hr boiler, steam distribution system and control system.

- 1991/92- Supply of Turnkey Steam Heating Plant for 6 nos of 60M Glove Processing Plants complete with 2 x 8 tons/hr boiler, steam distribution system, hot-air/hot-water heat-exchangers, and control system.

- 1994- Supply of Turnkey Steam Heating Plant for 10 nos of 100M Glove Processing Plants complete with 6 x 4 tons/hr boiler, steam distribution system, hot-air/hot-water heat-exchangers, and control system.

- 1999- Turnkey Supply of 4 production lines of Glove Manufacturing Plants with Patented High Productivity Double-Tiers Dipping Systems complete with 2 x 6 tons/hr Steam Heating Plants.

- 2003/4- Turnkey Supply of 2 production lines of Glove Manufacturing Plants with Patented High Productivity Double-Tiers Dipping Systems complete with 1 x 6 tons/hr Steam Heating Plants.

- 2006- Supply of Fuel Cost Savings 24 MBtu/hr Biomass Heat Generation System to replace Fuel-oil heating system for rubber products plant complete with automatic biomass fuel feeding system of moving-floor bunker, screw-feeder, scraper conveyor feeder and buffer silo temperature controlled intermittent dumper, and smokeless biomass combustion system of dynamic pusher grate and multicyclone flue-gas dust arrestor

1.Design and Supply of 2 nos of 12 tons/hr Steam Biomass Heat Energy Generators c/w the full operation plant of steam distribution piping, condensate recovery system and controls.

2.Design and Supply of 12 units of Automatic Timber Kiln Dryers for timber drying and curing.

Customer : Maltaco Timber Teminal, Kuantan, Pahang

Location : Malaysia

Project Value : USD 1.90 Million Year : 2003/4

Scope of Works:

To Design, Fabricate, Erect, Test and Commission, and Guarantee;

1. Two Systems of 12 ton/hr Biomass Steam Heat Energy Generation Plants comprising of:

- Cast Iron Flat Grate Combi Type High Pressure Biomass Steam Boiler System for woodchips firing

- Biomass Storage Bunker c/w Conveyor Extractor System

- Environmental Control Multicylone Dust Scrubber System

- Flue Gas and Combustion Control Induce-fan Exhaust System

- Combustion Air Preheating System for burning wet Fuel

- Steam Piping, Pressure Regulation, Condensate and Flash Steam Recovery Systems for the Kiln Dryer Plant

2. Supply of 12 units of Automatic Timber Kiln Dryers for timber drying curing comprising of:

- Kiln Drying Chamber of panel construction with polyurethane insulation and zinc colorbond cladding, front loading doors and back sampling door.

- Fintube type steam heating coils and piping

- Moist air venting dampers complete with pneumatic cylinder controller

- Aerofoil aluminium axial hot air circulation fans complete with reverse flow controls and Class H high temperature sealed motors.

- Temperature and humidity controllers and sensors

- Steam fittings of separators, pressure reducers, temperature control valves and steam traps

1.Design and Supply of 1 nos of 6 tons/hr Steam Biomass Heat Energy Generators c/w the full operation plant of steam distribution piping, condensate recovery system and controls.

2.Design and Supply of one unit of Rubberwood Air-jet Veneer Dryer of 4 decks x 12 drying chambers.

Customer : Tatsang Furniture, Muar, Malacca

Location : Malaysia

Project Value : USD 0.75 Million Year : 2003/4

Scope of Works:

To Design, Fabricate, Erect, Test and Commission, and Guarantee;

1. One Systems of 6 ton/hr Biomass Steam Generation Plants comprising of:

- Cast Iron Flat Grate Combi Type High Pressure Biomass Steam Boiler System for woodchips firing

- Biomass Storage Bunker c/w Conveyor Extractor System

- Environmental Control Multicylone Dust Scrubber System

- Flue Gas and Combustion Control Induce-fan Exhaust System

- Combustion Air Preheating System for burning wet Fuel

- Steam Piping, Pressure Regulation, Condensate and Flash Steam Recovery Systems for the Timber Veneer Dryer Plant

2. Supply of one unit of Automatic Airjet Veneer Dryer for rubberwood timber veneer drying comprising of:

- Supply of 10 Drying Chambers, 2 Cooling Chambers of panel construction with rockwool insulation and metal plate cladding, with side doors for operation and maintenance

- Chain conveyor roller conveyors x 4 decks for conveying timber veneer

- Fintube type steam heat-exchangers for the 10 heating chambers

- Axial Aluminium Aerofoil hot air fans with high temperature sealed motors for the 12 chambers.

- High velocity airjet blowers for fast and efficient drying of timber veneer for the 10 chambers

- Feeding and Output Roller Conveyors

- Control systems for conveyor speed and steam

Design and Supply of one system of Fish-Meal Plant of 4 tons/hr complete with 1 no of 4 tons/hr Diesel Steam Heat Energy Generators full operation plant of feeders, conveyors, storage silos and steam distribution piping, condensate recovery system and controls.

Customer : South China Sea, Sibu, Sarawak

Location : Malaysia

Project Value : USD 0.45 Million Year : 2001

Scope of Works:

To Design, Fabricate, Erect, Test and Commission, and Guarantee;

One system of Fish-Meal Dryer of 4 tons/hr complete with one unit of 4 tons/hr Diesel Steam Heat Energy Generators Systems of 4 ton/hr comprising of:

1. Package diesel fired boiler of 4 tons/hr capacity comprising of;

- 3 pass steam generator with auto fuel burner and controls

- Water level and feed pump and controls

- Safety valves and steam of-take valve and fittings

- Water softener, feedtank and condensate recovery

- Steam distribution and supply piping and controls

2. One unit rotary cooker with steam heated jacket and spiral steam tube conveyor c/w variable speed drive system

3. Seven units rotary dryers with steam jacket and spiral steam tube conveyor c/w variable speed drive system

4. Screw type feeding, and transferring conveyors

5. Moisture exhaust system for rotary dryers

6. Meal grinder and vibration separators

7. Water cooled screw conveyors for fish meal

8. Storage silo with rotary valve extractor

9. Water scrubber system for cleaning fish meal evaporated exhaust

Design and Supply of Hot Oil Heating System for 6 units of Reactors for Alkyd Manufacturing and Supply of 1 no. of 8.0 M Btu/hr Diesel Fired Thermal Oil Heat Energy Generators.

Customer : Corschem Sdn Bhd, Beranang, Negri Sembilan

Location : Malaysia

Project Value : USD 0.70 Million Year : 2005

Scope of Works:

To Design, Fabricate, Erect, Test and Commission, and Guarantee;

One System of Hot Oil Heating System for 6 units of Reactors for Alkyd (Oil based paint resin) Manufacturing and Supply of 1 no. of 8.0 M Btu/hr Diesel Fired Thermal Oil Heat Energy Generators comprising of:

1. Package diesel fired Thermal Oil Heater comprising of;

- Double helcal coil 3 pass heat generator with auto fuel burner and controls

- Hot oil circulation pump, valves and heat distribution and supply system

- System air deaerator, expansion and drain tanks

- Heat recovery unit for energy conservation

2. 6 units of stainless steel SS316 reactor vessels with external semipipe heating jackets and internal motorized stirrers of capacities of 10 tons x 2 units, 5 ton x 3 units and 1 tons x 1unit. Two

3. Thermal oil distribution and supply system to the reactors

- Temperature control system of control valves, temperature sensors and PLC controllers for the reactors

- Rockwool insulation for the reactors and piping complete with aluminium cladding

Design and Supply of Steam Heating System for a Palm Oil Refinery for Refining, Bleaching and Deodorising and Supply of 1 no. of 8.0 tons/hr Fuel-oil Fired Steam Boiler.

Customer : Jomalina Sdn Bhd, Banting, Selangor

Location : Malaysia

Project Value : USD 0.38 Million Year : 1995

Scope of Works:

To Design, Fabricate, Erect, Test and Commission, and Guarantee;

One system of Steam Heating System for a Palm Oil Refinery for Refining, Bleaching and Deodorising and Supply of 1 no. of 10 tons/hr Fuel-oil Fired Steam Boiler comprising of;

- Package diesel fired boiler of 10 tons/hr capacity comprising of;

- 3 pass steam generator with auto fuel burner and controls

- Water level and feed pump and controls

- Safety valves and steam of-take valve and fittings

- Water softener, feedtank and condensate recovery

2. Steam distribution and supply piping and controls to;

- Palm oil storage tank heating

- Degumming process

- Bleaching Tanks

- Filtration System

- RBD Oil Storage