- Input: T/C, RTD, mV, Resistance.

- Output: 4-20 mA (2-wire) with HART signal.

- Power Supply: 9-36 VDC.

- Cable Entry: M20 thread or 1/2″ NPT (Female).

- Process Connection: Thread or Flange.

- High precision: Uses advanced capacitance, silicon, or ceramic sensors for accurate pressure measurement.

- Reliable signal transmission: 4~20mA DC two-wire system ensures long-distance and interference-resistant data transmission.

- Durable & versatile: Aluminum die-casting shell with corrosion-proof, explosion-proof, and isolation-proof options.

- User-friendly design: Compact, lightweight, and available with LED, LCD, or pointer gauge displays.

- Broad compatibility: Measures viscous, crystallized, and corrosive mediums across a wide pressure range (-95kPa to 60MPa).

- Customizable configurations: Offers various sensor types, explosion-proof ratings, connection types, and measuring ranges.

- Precise temperature monitoring: Converts RTD and thermocouple signals into reliable industry-standard outputs.

- Versatile sensor compatibility: Supports Pt100, Cu50, and TC types J, K, E, T, B, S.

- Broad measurement range: Works from -200°C to +600°C for diverse applications.

- Stable & customizable output: Provides a 4-20mA (2-wire) signal, with optional HART protocol for remote configuration.

- Durable & adaptable design: Offers various protection tube materials, diameters, and installation configurations.

- Wide industrial applications: Ideal for water treatment, chemical processing, HVAC, and food production.

- High precision: Offers reference accuracy of ±0.075% (B model) and ±0.1% (C model).

- Reliable signal output: Provides a 4-20mA DC signal with HART communication for remote setup and diagnostics.

- Long-term stability: Maintains ±0.1% span stability over three years.

- Robust industrial design: IP67-rated aluminum housing, 316L stainless steel diaphragm, and optional explosion-proof certifications.

- Wide measurement range: Covers spans from 0.2kPa up to 3MPa, suitable for liquid, gas, and steam applications.

- Customizable configurations: Flexible options for accuracy, diaphragm materials, process connections, and display units.

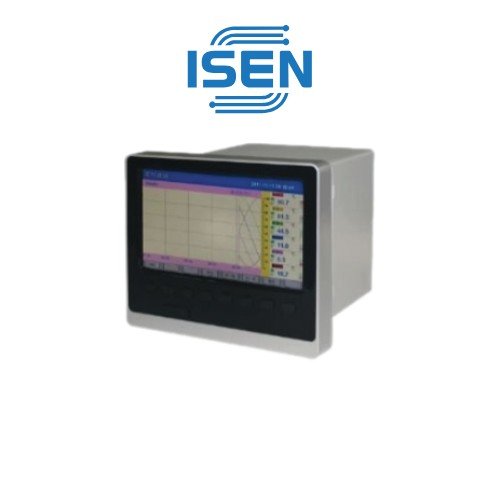

- High-precision measurement: Accuracy of ±0.1% with stability maintained over 2 years.

- Versatile input compatibility: Accepts T/C (K, S, B, E, J, T, R, N) and RTD (CU50/PT100), plus mV and resistance signals.

- HART communication: Allows for easy remote setup and monitoring.

- User-friendly interface: Features a rotatable, backlit LCD screen with clear display functions.

- Robust & durable design: IP67-rated housing with explosion-proof and weather-resistant capabilities.

- Wide industrial applications: Suitable for manufacturing, energy, chemical processes, and automated systems.

- Design: Corrosion, high-pressure, and high-temperature resistant

- Standard Bore Diameter: 4.0 mm to 16.0 mm

- Max Standard Depth: Up to 1200 mm

- Material Options: Stainless steel alloys (e.g., SS 304, 316, 321, 310, etc.)

- Pressure Test: Nitrogen pressure test up to 10 MPa

- Optional Quality Tests: X-ray inspection, Helium leak test, Dye penetrant test

- Welding Standards: Compliant with ASME Boiler Code QW 201.1~2, WPS & PQR, JPI 7S-31