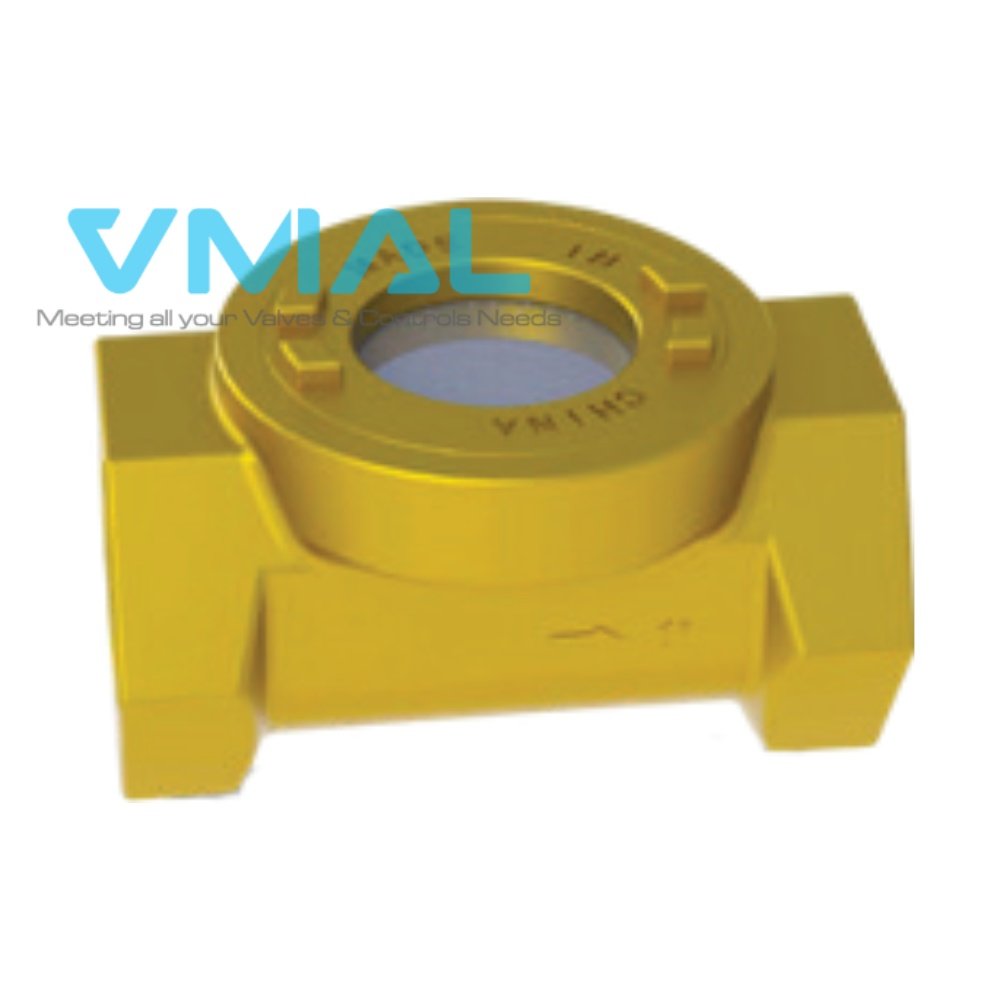

- Thương hiệu: VMAL

- Model: VMIYDF10-050/300

- Loại: Lọc Y (Y strainer)

- Kích thước (Size): DN50 (2 inch)

- Vật liệu thân (Body Material): Gang dẻo (Ductile Iron)

- Vật liệu lưới lọc (Screen Material): Inox 304 (Stainless Steel 304)

- Vật liệu đệm làm kín (Gasket/Seat Material): Cao su (Rubber)

- Kiểu kết nối (Connection): Lắp mặt bích, tiêu chuẩn PN16 (Flanged PN16)

- Nhiệt độ hoạt động tối đa (Operating Temp): 90°C.

- Efficient maintenance: Three-piece design allows in-line inspection and easy seat replacement.

- Full bore design: Ensures unrestricted flow and minimal pressure drop.

- Industry-standard compliance: Meets ANSI/ASME B16.34, API 598, and ISO 7/1 standards.

- Versatile connection options: Available with threaded and socket welding ends.

- Durable construction: Stainless Steel ball, SS410 stem, and PTFE seat for longevity.

- Wide applications: Ideal for chemical processing, oil & gas, water treatment, and industrial piping.

- Reliable overpressure protection: Automatically releases excess pressure to safeguard equipment.

- Industry-standard compliance: Designed according to DIN 3320, DIN 3202, DIN 2543-2545, and tested per DIN 3230.

- Durable construction: Made from GS-C25, stainless steel, Stellite, and copper alloy for longevity.

- Versatile applications: Ideal for hot oil, steam, and water systems in industrial environments.

- Efficient installation: Can be placed in pipeline commutation to reduce welding requirements.

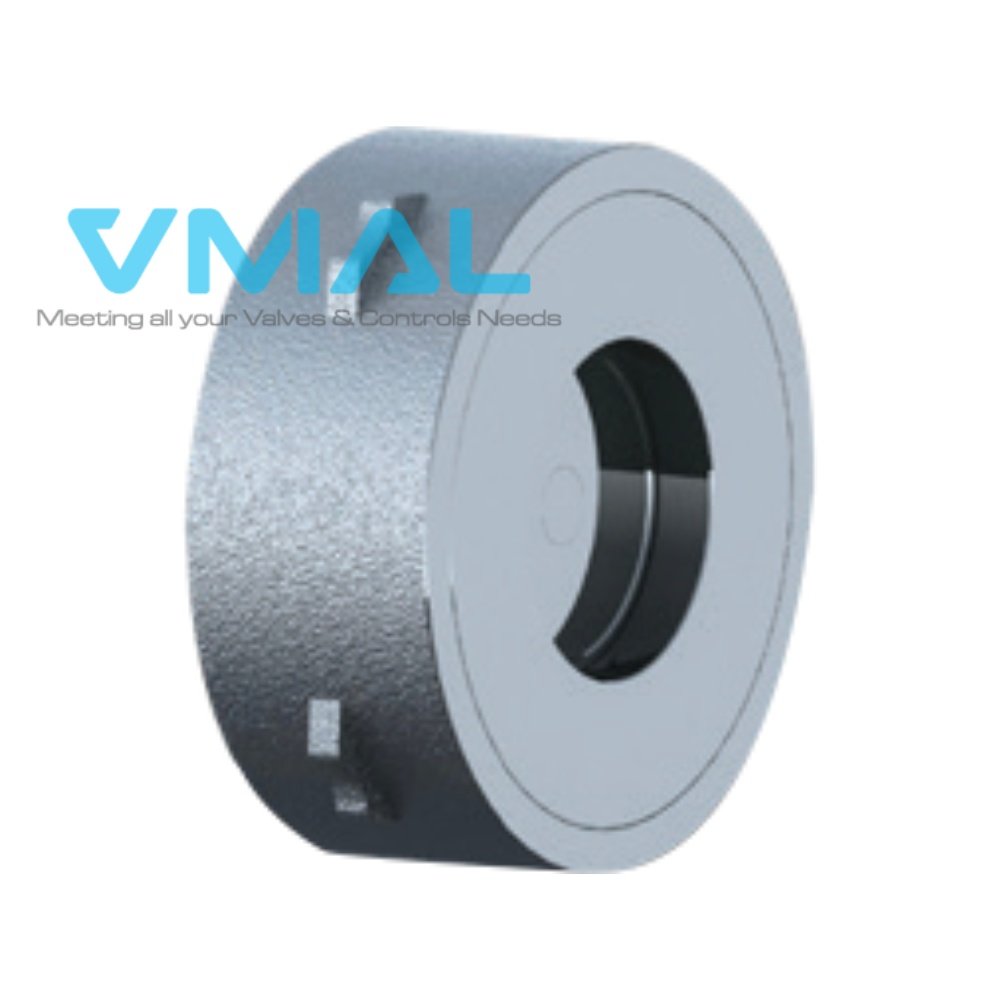

- Reliable backflow prevention: Self-sealing design ensures operational safety.

- Versatile installation: Spring-loaded disc allows horizontal, vertical, or angled mounting.

- Industry-standard compliance: Designed according to DIN 3356, DIN 3202, DIN 2543-2545, and tested per DIN 3230.

- Durable construction: Made from GS-C25, stainless steel, Stellite, and flexible graphite for longevity.

- Wide applications: Ideal for hot oil, steam, and water systems in industrial environments.

- Reliable overpressure protection: Automatically discharges excess pressure to safeguard equipment.

- Industry-standard compliance: Designed according to DIN 3320, DIN 3202, DIN 2543-2545, and tested per DIN 3230.

- Durable construction: Made from GS-C25, stainless steel, Stellite, and copper alloy for longevity.

- Versatile applications: Ideal for hot oil, steam, and water systems in industrial environments.

- Efficient installation: Can be placed in pipeline commutation to reduce welding requirements.

- Superior flexibility: Twin-sphere design absorbs axial and lateral movements more effectively than single-sphere joints.

- Reliable vibration & noise reduction: Protects piping systems from stress and premature wear.

- Durable construction: Made from high-quality EPDM or NBR rubber with carbon steel flanges.

- Industry-standard compliance: Meets API609, BS5155, DIN3202, ISO5752, and flange standards like DIN, ANSI, and JIS.

- Versatile applications: Ideal for HVAC, water treatment, food processing, petrochemical plants, and shipbuilding.

- Wide displacement range: Handles axial stretching (30-35mm), compression (50-60mm), and lateral movement (35-45mm).