- Body & Disc: Cast Iron (CI) / Ductile Iron (DI)

- Bonnet & Rocking Arm: Ductile Iron (DI)

- Sealing Ring: Brass

- Gasket: Graphite

- Pin, Stud & Nut: Carbon Steel (CS)

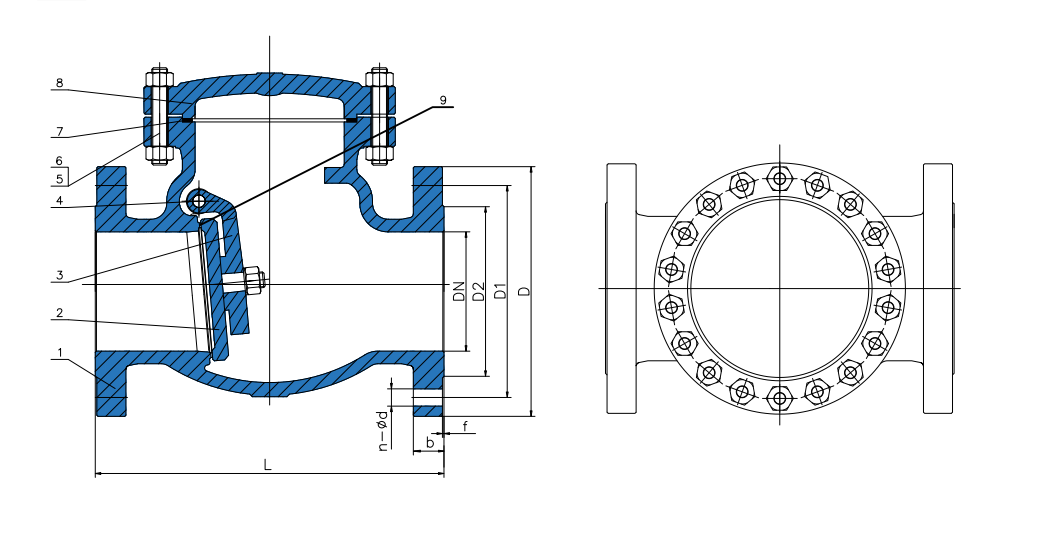

VMAL Swing check valve

Description

In critical fluid control systems across various industries, preventing backflow is paramount to ensuring operational safety, efficiency, and integrity. The Swing check valve stands as a fundamental component in achieving this, and Valvelink is proud to present the robust and versatile VMAL Swing check valve, engineered to meet the highest standards of performance and durability.

This flanged Swing check valve is meticulously designed to allow fluid to flow in one direction while automatically preventing reverse flow, safeguarding your equipment from potential damage and your processes from contamination.

Superior Design and Construction

The VMAL Swing check valve is built with high-quality materials to ensure longevity and consistent performance. The main body and disc are constructed from either Cast Iron (CI) or Ductile Iron (DI), offering excellent strength and corrosion resistance. The robust design is further complemented by a Ductile Iron bonnet and rocking arm, a carbon steel pin, and a durable brass sealing ring for a tight and reliable seal.

Key Material Specifications:

- Body & Disc: Cast Iron (CI) / Ductile Iron (DI)

- Bonnet & Rocking Arm: Ductile Iron (DI)

- Sealing Ring: Brass

- Gasket: Graphite

- Pin, Stud & Nut: Carbon Steel (CS)

Adherence to International Standards

To ensure seamless integration into a wide array of existing and new systems, the VMAL Swing check valve complies with a comprehensive set of international standards. This commitment to universal standards simplifies specification and installation for our global clientele.

- Type: Flange

- Face to Face Standards: API609, BS5155, DIN3202-F6, ISO5752

- Flange Compatibility: DIN, BS, UNI, ISO, ANSI, AS, JIS

- Mounting Flange: ISO5211

Performance and Dimensions

Engineered for reliability, the VMAL Swing check valve operates efficiently under a working pressure of PN16 (200PSI). Valvelink offers an extensive range of sizes, from DN50 (2″) to DN600 (24″), to meet diverse application requirements. Detailed dimensions for both PN10 and PN16 flanges are available to ensure a perfect fit for your specific needs.

Example Dimensions for PN16 Flange:

| SIZE (DN) | Face to Face (L) (mm) | Flange Diameter (D) (mm) | Bolt Circle Dia. (D1) (mm) | Flange Holes (n-Ød) |

| 50 | 200 | 165 | 125 | 4-19 |

| 100 | 300 | 220 | 180 | 8-19 |

| 200 | 500 | 340 | 295 | 12-23 |

| 300 | 700 | 460 | 410 | 12-28 |

| 600 | 1300 | 840 | 770 | 20-37 |

For a complete list of dimensions, please refer to the product datasheet.

Versatile Applications

The reliability and robust construction of the VMAL Swing check valve make it the ideal choice for a multitude of industries and applications, including:

- HVAC

- Water Supply & Sewage

- Food & Beverage

- Chemical/Petrochemical Processing

- Power and Utilities

- Paper and Pulp

- Ship Building

For a reliable, standards-compliant, and durable Swing check valve, look no further than the VMAL series from Valvelink. Contact us today to learn how we can meet your valve and piping needs with precision and professionalism.